AccuLINK Software Package

Тип: Article

The Thermo Scientific™ AccuLINK Software Package continuously compares online analytical data with lab values to implement timely automatic calibrations and ensure the highest possible online accuracy in cement analysis. It references neutron activation analysis data measured in real-time with the Thermo Scientific™ CB Omni Agile Online Elemental Analyzer to gold standard X-Ray Fluorescence (XRF) data for cement composition measured with the ARL series of laboratory analyzers (or with instruments from alternative suppliers) to enable consistent operation to an optimal set-point. Use AccuLINK to access lab accuracy online, with minimal manual input, for highly effective diagnostics and troubleshooting and to safeguard operation at a setpoint that maximizes profitability.

Reflecting our capabilities as a one-stop shop for laboratory and online elemental analysis for cement, AccuLINK continuously calibrates your online crossbelt analyzer ensuring it consistently operates at peak accuracy, for optimum operational efficiency. Key features include:

- Easy-to-use, for enhanced data quality with minimal input from lab personnel

- Flexible, in-depth statistical and graphical data analysis including robust scatter and time series plots, for productive information gathering with minimal training

- Fully automatic calibration updates, for consistently high online accuracy

- Automatic outlier screening, for rigorous and robust data analysis

Using AccuLINK Software Package to link lab to line

Introduction

Online analyzers measure at high frequency, providing a real-time data stream far more suitable for responsive process control than the periodic measurements associated with offline measurement in the lab. On the other hand, offline measurements typically set the benchmark with respect to accuracy and precision. For cement manufacturers, for example, lab-based X-ray fluorescence spectroscopy (XRF) is the ‘gold standard’ technique for elemental analysis while PGNAA is the technique of choice for online, cross-belt, real-time measurements on the plant.

Using these two techniques synergistically supports the highly efficient manufacture of cement to exacting standards but involves the effective management of discrepancies between lab and online measurements. Lab-based XRF measurements benefit from superior control of the sample environment and the ability to run daily reference standards. In contrast, online PGNAA analysis is an online analysis technique and is subject to dynamic changing environments which can be difficult to control.

Calibrating online measurements to robustly match offline data is necessary to ensure proper quality and process control. Conventionally, operators carry out this process manually, using tools such as Microsoft Excel™ to run linear regressions, and implementing any detected need for change on a relatively infrequent basis making it less than optimal.

Software

Thermo Scientific™ AccuLINK™ Software is a statistical software package and calibration tool that continuously compares lab and online data, automatically recalibrating the online system when a potential drift is detected. It was originally developed to link the Thermo Scientific™ CB Omni Agile Online Elemental Analyzer working with the Thermo Scientific™ RAMOS™ Raw Mix Optimization Software to the ARL™ family of XRF spectrophotometers but application now extends to many other brands of lab based analyzers. Flexible and highly configurable, AccuLINK generates a wide range of statistical metrics and graphics tailored to customer-specific operating practice to support effective troubleshooting, as well as ensuring agreement between the lab and online analyzers.

Screenshots from AccuLINK help to illustrate its capabilities. Figure 1 is the bias summary screen which displays hourly lab data vs. online analyzer trends for the last two to three days. The bar chart beneath showing average bias between the two over the last three months with each bar representing a calibration period. Here, Lime Saturation factor (LSF), Silica The bar chart beneath showing average bias between the two over the last three months with each bar representing a calibration period. Here, Lime Saturation factor (LSF), Silica. Modulus (SM), Iron Modulus (IM) and iron oxide (Fe2 O3 ) are the focus, but customers can tailor this selection to match their specific process chemistry.

Figure 2 is the oxide calibration screen which shows lab vs. analyzer values for a single detector, and for a specific oxide, as a scatter plot and in trend form for a chosen calibration period. It highlights outlying points which can be excluded from drift analysis using configurable rules.

Figure 3 is the calibration overview screen which includes current calibration constants and summarizes the performance of individual detectors for specific oxides. This data alert operators to the need for recalibration for specific detectors, but this recalibration process can be completely automated to minimize the manual input required.

Case study data

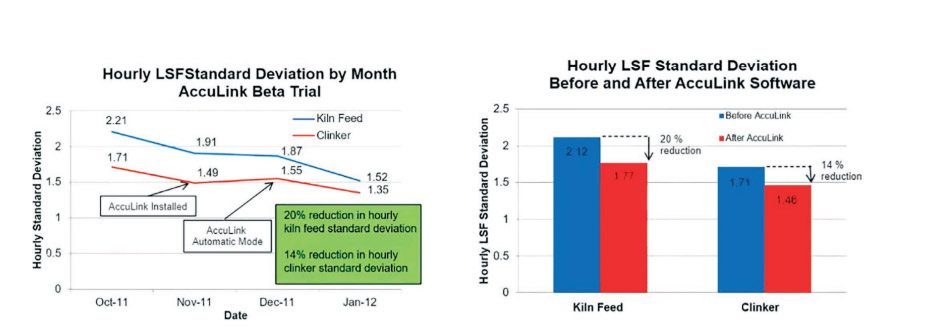

Figure 4 shows data from a trial with AccuLINK at the facility of a leading US cement manufacturer. During the trial AccuLINK was operated in manual mode for two weeks to establish confidence for a switch to automatic mode, where it then remained. Key gains include a 20% reduction in the variability of the LSF of the kiln feed and a corresponding 14% reduction in the variability of the LSF of the clinker.

Figure 4 Cement manufacturers work hard to monitor and control the LSF of the kiln feed in the face of naturally varying raw materials and within the constraint of minimizing the cost of such materials. Lower LSF variability translates into greater stability in the kiln, thereby delivering energy savings and extending refractory life. These results therefore illustrate the potential for AccuLINK to deliver major economic return for a plant already benefiting from online LSF measurement. At the same time using AccuLINK minimizes the manual effort associated with keeping online analysis aligned with lab data, further augmenting the savings made. Learn more at thermofisher.com

Conclusion

AccuLINK allows cement manufacturers to ensure agreement of their online PGNAA system by anchoring performance to the quality control standard of lab-based XRF measurement. It delivers fully automatic, high frequency alignment of the online analyzer with minimal manual input, making it easier for cement manufacturers to benefit from the synergistic benefits of having both lab and online measurement in place. In this way AccuLINK underpins the precision control needed to make highly consistent, high-quality cement, as efficiently as possible.